Assembling fine furniture coasters involves understanding both table protection and maritime history, from early designs to modern variations.

These instructions guide you through securing bases, tops, and feet, ensuring your surfaces remain pristine.

Consider the nuances of materials and designs, like round versus square, while referencing manufacturer support for assistance.

Understanding the Importance of Coasters

Coasters, seemingly simple items, play a crucial role in preserving the beauty and longevity of fine furniture. Beyond basic table protection, they represent a thoughtful consideration for both aesthetics and functionality. Historically, as evidenced by discussions around early designs, coasters evolved from purely practical items to decorative elements.

The need to shield surfaces from condensation rings, heat damage, and scratches is paramount. Fine furniture, often representing a significant investment, deserves this extra layer of care. Even discussions about maritime vessels – referencing “coasters” as small ships – highlight a historical association with careful transport and preservation.

Choosing the right coaster, and assembling it correctly, demonstrates respect for craftsmanship and ensures your furniture remains pristine for years to come.

Overview of Fine Furniture Coaster Types

Fine furniture coasters exhibit a diverse range of designs, materials, and construction methods. Common types include those with felt or cork bases for superior grip and surface protection, and those featuring absorbent materials to capture condensation; Discussions referencing ship “coasters” hint at a historical practicality influencing modern designs.

Materials vary widely, from wood and stone to metal and acrylic, each offering a unique aesthetic. Assembly often involves attaching a base to a decorative top, sometimes with added protective feet. Variations exist in shape – round, square, or even uniquely sculpted – influencing both style and functionality.

Understanding these distinctions is key to selecting and assembling the appropriate coaster for your specific furniture and needs.

Tools and Materials Required for Assembly

Essential tools include screwdrivers, adhesives, and potentially a soft cloth. Components typically involve coaster tops, bases, and protective feet, if included.

Essential Tools List

For successful fine furniture coaster assembly, a curated toolkit is vital. A Phillips head screwdriver is paramount, often needed for securing the coaster top to its base. A flathead screwdriver may also be necessary, depending on the fastener type.

Consider a small rubber mallet for gently tapping components into place, avoiding damage to delicate finishes. High-quality wood glue or adhesive is crucial for a lasting bond, especially if the kit doesn’t rely solely on screws.

A soft cloth protects surfaces during assembly and cleanup. Precision tweezers can assist with handling small parts like protective feet. Finally, safety glasses are recommended to shield your eyes from debris.

Identifying Coaster Components

Before beginning assembly, familiarize yourself with all parts. Typically, a fine furniture coaster kit includes a coaster base – often wood, stone, or acrylic – and a coaster top, potentially differing in material.

Small, self-adhesive protective feet are frequently included to prevent scratching surfaces. Screws or fasteners will secure the top to the base; verify their type and quantity.

Some kits may feature decorative elements or inlays. Carefully compare the components against the parts list provided by the manufacturer. Understanding each piece’s function streamlines the assembly process and minimizes errors, ensuring a polished final product.

Step-by-Step Assembly Instructions

Follow these instructions carefully: attach the base, secure the top with provided fasteners, and add protective feet if included for optimal results.

Attaching the Coaster Base

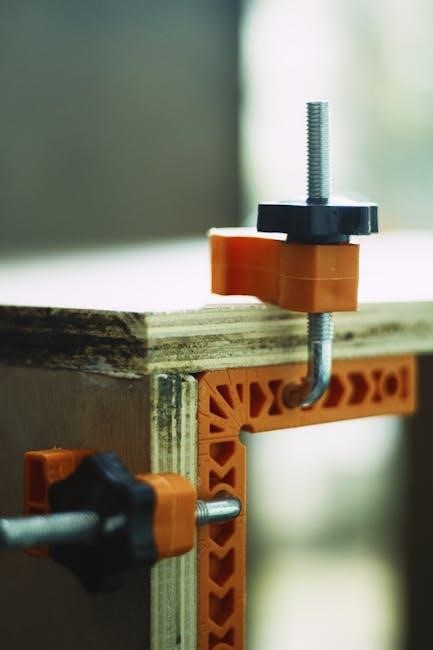

Begin by carefully positioning the coaster base onto the underside of the coaster top. Ensure proper alignment, as misaligned parts can lead to instability. Most fine furniture coasters utilize screws for secure attachment; locate the pre-drilled holes on both components.

Using the appropriate screwdriver (refer to the tools list), gently insert the screws into the holes. Avoid over-tightening initially, as this could strip the screw threads or damage the wood. Tighten the screws in a diagonal pattern – top left, bottom right, top right, bottom left – to distribute pressure evenly.

Once all screws are in place, gradually increase the tightness, checking for wobble or unevenness. A firm, secure attachment is crucial for preventing damage to your furniture.

Securing the Coaster Top

With the base now attached, focus on reinforcing the connection between the base and the coaster top. Inspect the initial screw placements, ensuring they are flush and secure. If the coaster design incorporates additional fastening methods – such as adhesive or small wooden dowels – prepare those now.

Apply a small amount of wood glue (if applicable) to the joining surfaces before fully tightening the screws. This adds an extra layer of stability and prevents future loosening. Re-tighten all screws, again using a diagonal pattern, to ensure even pressure distribution.

Finally, gently test the connection by applying slight pressure. A firmly secured top is essential for preventing spills and protecting your furniture.

Adding Protective Feet (if applicable)

Many fine furniture coasters include protective feet to prevent scratching delicate surfaces. These feet are typically made of felt, cork, or rubber and attach to the underside of the coaster base. Identify the correct placement points – usually at each corner – before beginning.

If the feet are self-adhesive, ensure the base surface is clean and dry for optimal adhesion. Peel off the backing and carefully align the foot before pressing firmly into place. For screw-on feet, use the provided screws and a screwdriver, avoiding over-tightening.

Inspect each foot to confirm it’s securely attached and level, contributing to a stable and protective base.

Troubleshooting Common Assembly Issues

Addressing misaligned parts, stripped screws, or wobbling requires patience and careful re-evaluation of assembly steps. Ensure proper alignment and secure fastening.

Dealing with Misaligned Parts

Misalignment during coaster assembly is a frequent issue, often stemming from uneven surfaces or slightly warped components; Before forcing anything, carefully inspect all parts for defects or damage. Loosen any previously secured screws to allow for adjustments. Gently apply pressure to realign the pieces, ensuring a flush fit.

If misalignment persists, double-check the orientation of each component against the instructions. Sometimes, a part is inadvertently installed backward. Avoid excessive force, as this can strip screws or damage the fine furniture finish. Consider using a rubber mallet with a protective cloth to tap pieces into place. If significant misalignment remains, consult the manufacturer’s support for guidance, as forcing the issue could void any warranty.

Addressing Stripped Screws

Stripped screws are a common frustration during fine furniture coaster assembly. If a screw spins freely without tightening, stop immediately to prevent further damage. Attempting to use a larger screwdriver head might provide a better grip, but proceed cautiously. A rubber band or steel wool placed between the screwdriver and screw head can sometimes improve traction.

For severely stripped screws, a screw extractor kit is highly recommended. These kits contain specialized bits designed to grip and remove damaged screws. Avoid over-tightening replacement screws, as this can easily lead to stripping. If you’re unable to resolve the issue, contact the manufacturer for replacement parts or professional assistance; forcing it could damage the coaster’s integrity.

Resolving Wobbling Issues

Wobbling coasters detract from both aesthetics and functionality. First, ensure all screws are fully tightened, but avoid over-tightening which can strip them. Inspect the coaster base and top for any unevenness or warping. If the wobble persists, check the protective feet – are they all the same height and securely attached?

Small felt pads can be strategically applied to the shorter legs to level the coaster. For significant imbalances, consider slightly loosening screws, gently pressing down on the higher corner, and re-tightening. If the issue remains unresolved, contacting the manufacturer for guidance or a replacement is advisable, as structural defects may be present.

Coaster Maintenance and Care

Regular cleaning and polishing preserve the beauty of fine furniture coasters, protecting against water damage, scratches, and general wear and tear.

Cleaning and Polishing Instructions

Maintaining the pristine condition of your fine furniture coasters requires a gentle approach. For daily upkeep, simply dust with a soft, lint-free cloth. Avoid abrasive cleaners, as these can damage the finish.

For more thorough cleaning, dampen the cloth with a mild soap solution – a few drops of dish soap in warm water will suffice. Wipe the coaster surface, then immediately dry with a separate, clean cloth.

Periodically, polishing can restore the luster. Use a furniture polish specifically designed for the coaster’s material (wood, stone, etc.), following the manufacturer’s instructions. Apply a small amount to a soft cloth and buff gently in circular motions. This will help protect against future scratches and maintain the beauty of your coasters for years to come.

Protecting Against Water Damage

Water is the enemy of many fine furniture coaster materials, particularly wood. Always use coasters under beverages to prevent rings and warping. Promptly wipe up any spills with a soft, absorbent cloth.

For coasters with a finish, consider applying a water-resistant sealant periodically, following the product’s instructions. This adds an extra layer of protection. Avoid placing hot, wet glasses directly onto the coasters, as the sudden temperature change can cause damage.

If your coasters are made of stone or ceramic, they are generally more water-resistant, but still benefit from prompt spill cleanup. Regular maintenance will ensure longevity and preserve the aesthetic appeal of your fine furniture coasters.

Preventing Scratches and Wear

To maintain the beauty of your fine furniture coasters, avoid abrasive cleaners. Instead, use a gentle polish specifically designed for the coaster’s material. Regularly dust the coasters with a soft cloth to remove particles that could cause scratches.

When not in use, store coasters in a protective location, such as a felt-lined drawer or a coaster holder, to prevent them from being knocked against hard surfaces; Avoid sliding coasters across tables, as this can lead to wear on both the coaster and the furniture.

Consider using felt pads on the underside of the coasters to further protect surfaces from scratches and reduce noise.

Historical Context of Coasters & Small Vessels

Early coasters protected tables, while “coaster” also referenced small ships like the 1952 Moby Dick, highlighting a dual historical meaning.

Early Coaster Designs (Table Protection)

Historically, the primary function of a coaster was, and remains, simple: to shield furniture surfaces from damage caused by condensation and spills. Early iterations weren’t the refined pieces we see today, but rather practical solutions crafted from readily available materials.

These initial designs likely involved felt, cork, or simple woven mats, prioritizing functionality over aesthetics. The need arose alongside the increasing popularity of beverages served in glasses and mugs, protecting valuable wooden tables from unsightly rings and water damage.

As furniture craftsmanship evolved, so too did coaster designs, gradually incorporating decorative elements. However, the core purpose – preservation – remained constant, laying the foundation for the fine furniture coasters we assemble today.

The “Coaster” as a Small Ship (Maritime History)

Interestingly, the term “coaster” possesses a fascinating parallel history within maritime terminology. A “coaster” traditionally referred to a small, single-masted trading vessel frequently navigating coastal routes. These vessels, like the Mobby Dick built in 1952, and the Patricia, were workhorses of short-sea trade.

These coastal traders, often under 200 tons, transported goods between ports, relying on favorable winds and skilled seamanship. The name reflects their habitual “coasting” along shorelines.

While seemingly unrelated to furniture, this historical context adds a layer of depth to the word, reminding us of a time when small vessels played a vital role in commerce and daily life, a subtle echo in the objects we assemble.

Fine Furniture Coaster Design Variations

Coasters exhibit diverse designs, ranging from classic round shapes to modern square forms, utilizing materials like wood, stone, or metal for elegance.

Round vs. Square Coasters

The choice between round and square coasters often comes down to aesthetics and practicality. Round coasters, historically favored, offer a classic, softer look that complements many furniture styles. Their lack of corners prevents snagging on tablecloths or napkins, contributing to a smoother dining experience.

Square coasters, on the other hand, provide a more contemporary and geometric aesthetic. They maximize surface area for better spill containment, which is particularly useful for larger glasses or mugs. The straight edges can align well with modern furniture designs, creating a cohesive look. Ultimately, the selection depends on personal preference and the overall décor of the space where the coasters will be used.

Materials Used in Fine Furniture Coasters

Fine furniture coasters showcase a diverse range of materials, each contributing unique qualities. Wood, particularly hardwoods like oak, maple, and walnut, offers durability and a classic aesthetic; Stone coasters, such as marble or slate, provide a sophisticated look and excellent heat resistance, ideal for hot beverages.

More contemporary designs incorporate materials like acrylic or resin, offering vibrant colors and modern appeal. Metal coasters, often stainless steel, are durable and easy to clean. The core material is frequently paired with felt or cork bases to prevent scratching delicate furniture surfaces, ensuring both protection and elegance.

Safety Precautions During Assembly

Always protect your work surface and handle small parts carefully to avoid mishaps during coaster assembly. Prioritize a safe, organized workspace.

Protecting Your Work Surface

Before beginning the assembly of your fine furniture coasters, it’s crucial to safeguard your work area. Delicate finishes on tables or countertops are easily scratched by coaster components or tools. A layer of protective material is essential.

Consider using a soft blanket, a drop cloth, or even several layers of newspaper to create a barrier. This prevents accidental damage during the assembly process. Ensure the surface is stable and well-lit for optimal visibility and control.

Having a dedicated, protected space minimizes the risk of scratches, dents, or other imperfections to your existing furniture while you focus on assembling your new coasters. A little preparation goes a long way!

Handling Small Parts Safely

Fine furniture coaster assembly often involves numerous small components – screws, pads, and potentially decorative elements. These parts present a potential choking hazard, especially for children and pets. Maintain a tidy workspace to prevent loss or accidental ingestion.

Keep all small parts contained within a designated area, such as a small bowl or tray. Avoid scattering them across a large surface. When handling screws, use a magnetic screwdriver to prevent drops and facilitate accurate placement.

Exercise caution and focus during assembly to minimize the risk of injury or lost components. Prioritize a safe and organized approach throughout the entire process.

Resources for Additional Assistance

Manufacturer websites offer detailed support, while online forums and communities provide valuable insights and troubleshooting tips for fine furniture coasters.

Manufacturer’s Website & Support

Directly accessing the fine furniture manufacturer’s website is often the most reliable starting point for assembly assistance. These sites frequently host dedicated support sections, including downloadable digital manuals, frequently asked questions (FAQs), and illustrative video tutorials demonstrating each assembly step.

Many manufacturers also provide direct customer support channels, such as email or phone lines, allowing you to connect with a representative who can address specific concerns or clarify ambiguous instructions. Look for a “Contact Us” or “Support” link prominently displayed on their homepage.

Furthermore, some companies maintain online knowledge bases or chat features for immediate assistance. Registering your product may unlock access to exclusive support resources and warranty information, ensuring a smooth assembly experience.

Online Forums & Communities

Leveraging the collective knowledge of online forums and communities dedicated to furniture assembly can prove invaluable. Platforms like Reddit (r/furniture) or dedicated home improvement forums often feature threads discussing specific fine furniture brands and models, including assembly challenges and solutions.

Searching these forums for keywords related to your coaster set can reveal shared experiences, helpful tips, and even photographic evidence of successful assemblies.

Don’t hesitate to post your own questions, providing details about your specific issue; experienced members are often eager to assist. Remember to respect community guidelines and contribute constructively, fostering a collaborative environment for all.